WELDING SYSTEM

RTG’s welding processes are coordinated by International Welding Engineers. Welders qualified in accordance with ISO 9606-1. RTG’s welders are also qualified to DNV-GL (Det Norske Veritas - Germanischer Lloyd) and LR(Lloyd’s Register ) standards. Welding Procedures are class approved (WPQR) with TÜV , DNV-GL, and LR, inaccordance with EN 15614-1 and DNV-GL rules for ships Pt.2Ch.4.

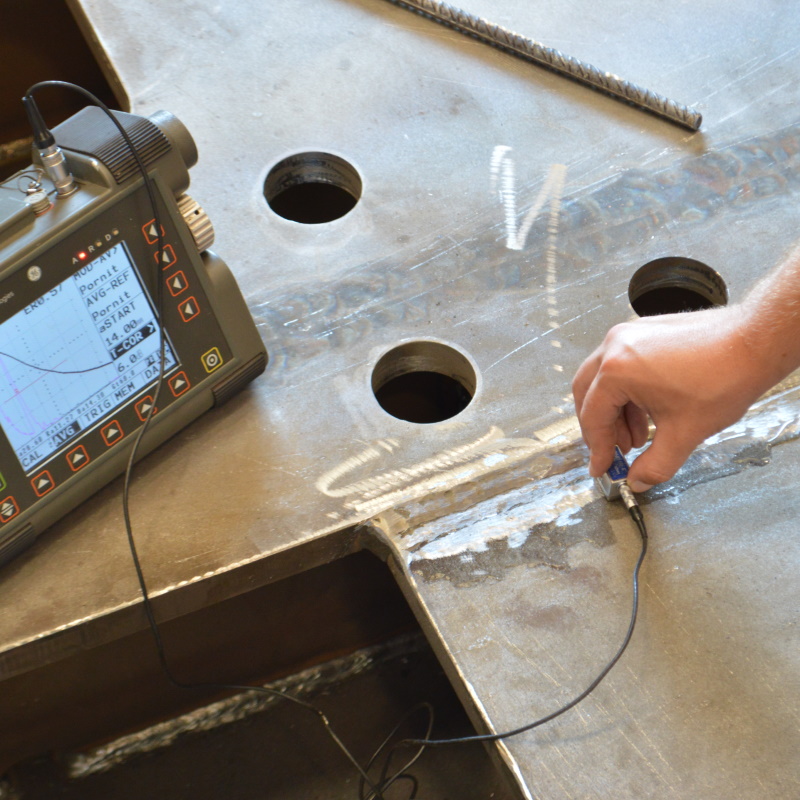

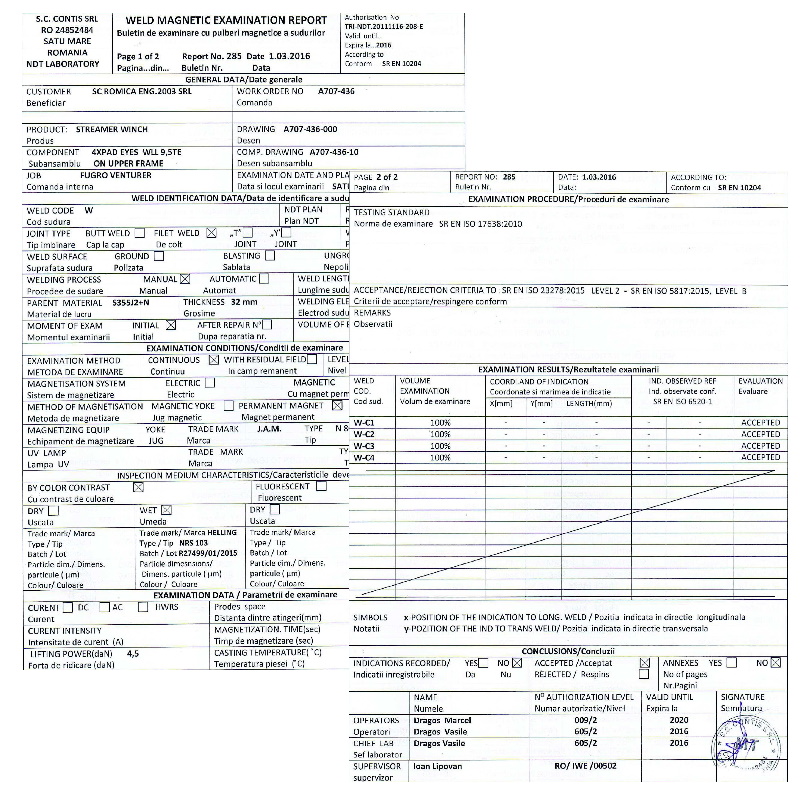

Non Destructive weld inspection is carried out by qualified engineers, certified for non-destructive testing according to ISO 9712, level 2 for UT, MT, PT.

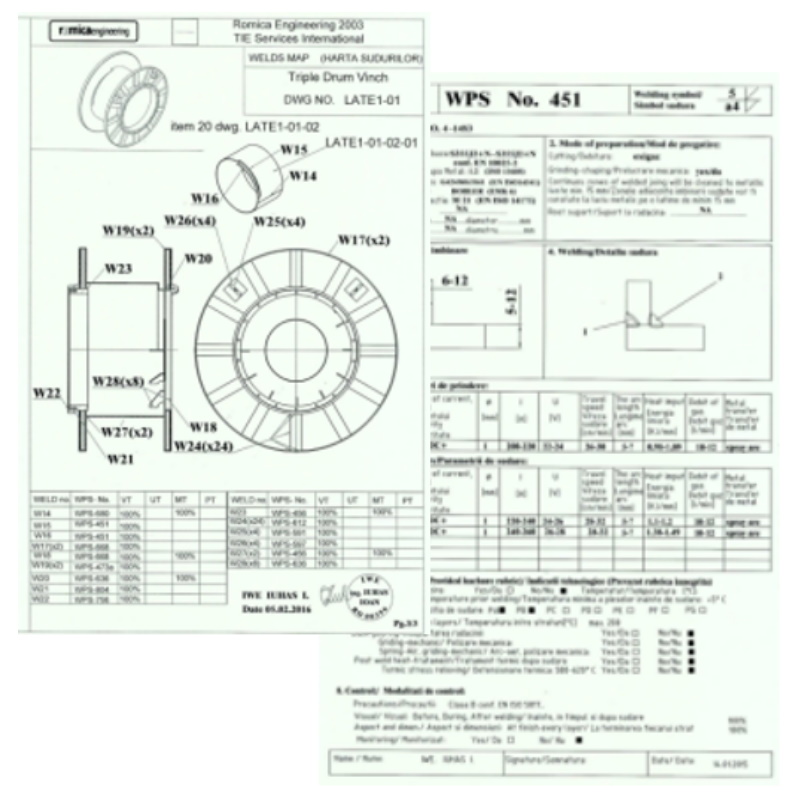

100% traceability is assured for all main structural welds: including, weld number, welder marking punch, welding procedure specification (WPS) and welding control (UT,MT, PT ).

The plant is certified by BV (Bureau Veritas Marine) – RECOGNITION FOR BV MODE II SCHEME for welded and machined metal structures, electric and hydraulic installation for winches and cranes.

Furthermore, we are under certification for welding in accordance with EN ISO 3834-2 and welding workshop approval with DNV-GL .

RTG is always looking to improve process quality and efficiency and as such invests in new generation technology, MIG/MAG welding machines (Fronius TPS 400i)

Non Destructive weld inspection is carried out by qualified engineers, certified for non-destructive testing according to ISO 9712, level 2 for UT, MT, PT.

100% traceability is assured for all main structural welds: including, weld number, welder marking punch, welding procedure specification (WPS) and welding control (UT,MT, PT ).

The plant is certified by BV (Bureau Veritas Marine) – RECOGNITION FOR BV MODE II SCHEME for welded and machined metal structures, electric and hydraulic installation for winches and cranes.

Furthermore, we are under certification for welding in accordance with EN ISO 3834-2 and welding workshop approval with DNV-GL .

RTG is always looking to improve process quality and efficiency and as such invests in new generation technology, MIG/MAG welding machines (Fronius TPS 400i)

External NDT Inspection

VT

Visual Testing

Visual Testing

PT

Penetrant Testing

Penetrant Testing

MT

Magnetic Particle

Magnetic Particle

UT

Ultrasonic Testing

Ultrasonic Testing